Textiles welding and cutting for woven and non-woven fabrics

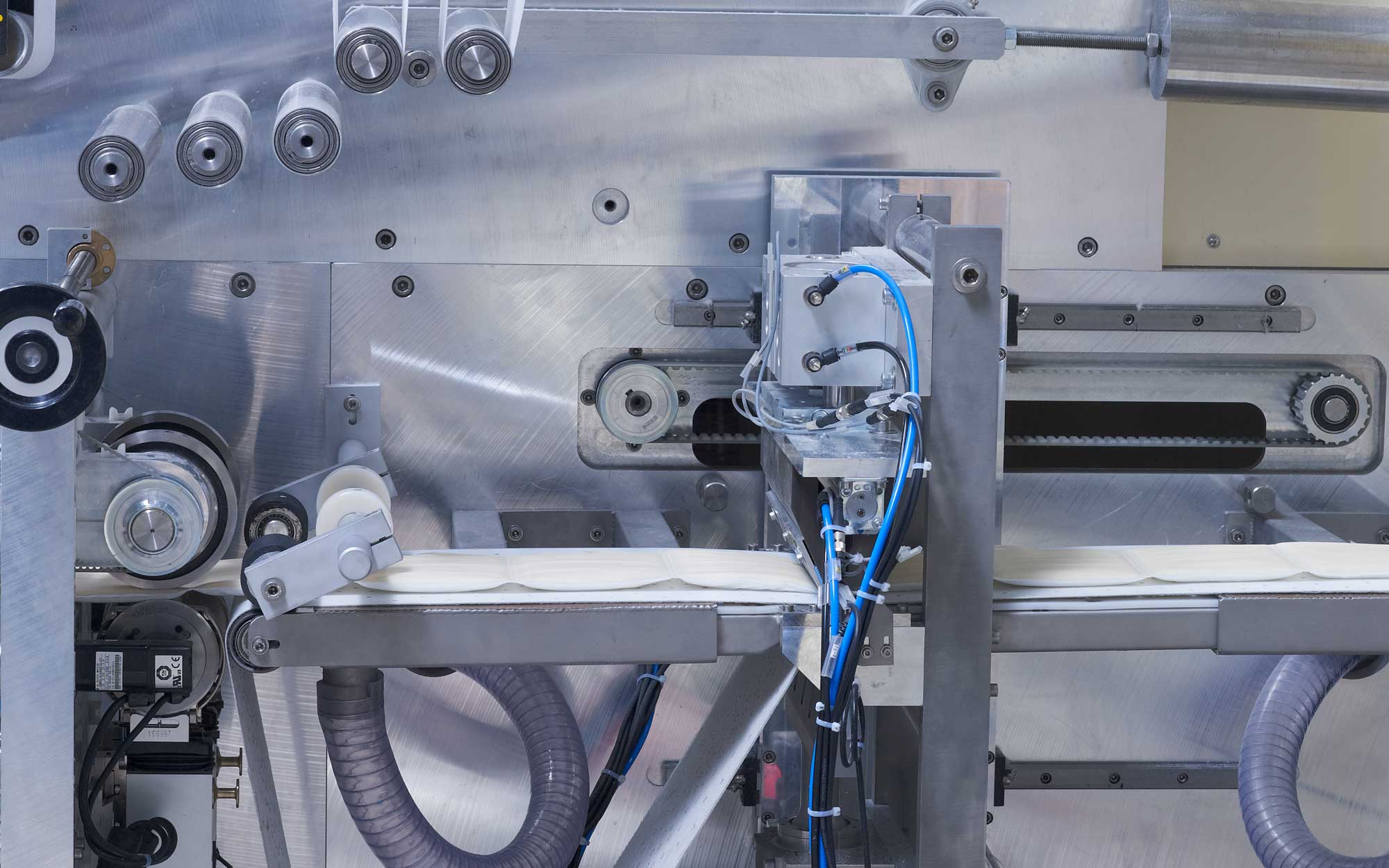

Our ultrasonic equipments can be used for various cutting, welding, and cauterisation operations.

For your woven fabrics (straps, suspenders, bracelets, belts, etc.) and non-woven products (nappies, towels, masks, etc.), we provide intermittent welding or high-speed continuous solutions with up to 400m/min.

Based on our experience and know-how, we provide turnkey equipment: in modules that can be integrated into your existing means, in standard manual presses or into fully customisable special machines.

Our ultrasonic textiles welding and cutting solutions

They trust us

The advantages of ultrasonic technology applied to welding and fabrics cutting

- High precision and quality welding/cutting

- Clean process: optimal hygiene with no binding products,

- Possibility of simultaneous cutting and welding, continuous or intermittent,

- No consumables and adhesives, no glues

- Elimination of heating time (compared to glue welding)

- Simplified maintenance

- No damage/burning of the material

- For welding, there is no direct mechanical contact between the vibrating element and the knurl/anvil (no tool wear)

- Multiple possibilities for welding patterns